UVA air-driven grinding spindle

Operating manual

STORAGE

1.the instrument housing in place

2.the mounted points or quills removed

3.the nose guard in position

4.the protective caps on the nipples.

Spindles kept in cold storage rooms, or exposed to cold weather, should be given time to warm up to room temperature before being started. This will allow any condensate to evaporate and ensure smooth running. Avoid splashing water or coolant fluids on the spindle while it is standing still. Moisture getting into the front end will seriously damage the bearings.

REPAIRS AND SERVICING

This must be carried out at our factory or at repair shops authorised by us. The name of your nearest repair shop is available from our agents. We would caution against "private" attempts to repair Turbo-Head. The job requires highly specialised equipment and if improperly done will lead to grave danger of accidents with the spindle.

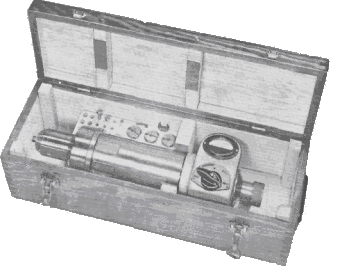

Style A spindles should be despatched for repairs and servicing in their carrying cases in accordance with points 1-4 above. Note that the carrying case itself is not suitable as a shipping box. Careful packing is required to avoid damage in transit.

Slyle B spindles must be packed in a wooden box with all protective fittings in place. Make sure the spindle is securely fastened and that the nose is not touching the end of the box, or can be jolted against it. If wood shavings or the like are used as a packing material wrap the spindle in several thicknesses of paper first.

Repair costs can be kept down by following directions for lubrication and keeping the dehumidifier unit dry and active.

Fig.9. Turbo-Head Style A carrying case