UVA air-driven grinding spindle

Operating manual

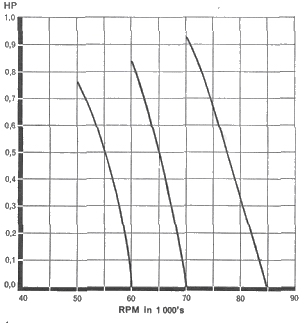

POWER OUTPUT

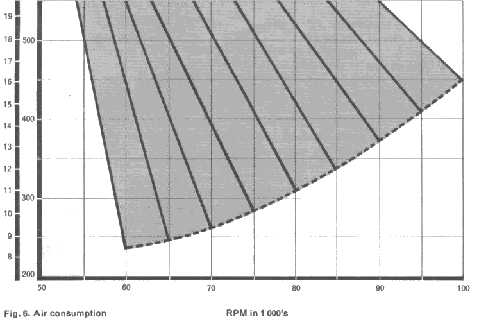

AIR CONSUMPTION

This is shown in Fig. 6. The no-load consumption is shown by the broken line and the under-load consumption by the fully drawn lines. As an example, a no-load consumption of 9.1 cfm (260 1/min.) can be read off for 70,000 rpm, a consumption of 9.8 cfm (280 1/min.) for 75,000 rpm, and so on. Loading increases air consumption. If, for instance, the spindle is set for 70,000 rpm and the speed under load drops to 63,000 rpm the air consumption will rise from 9.1 cfm to 15.75 cfm (from 260 to 450 1/min.). When the load is removed the air consumption at once drops to its no-load value. All figures given are in free air per minute and apply for an inlet pressure of 72 psi (5 kg/cm2).